Plastics division

Only cutting-edge products with reliable and rapid access to innovative and high-performance materials can be offered competitively on the world market today. Tailored plastics, plastic additives, plastic composites and plastic processing technologies play a central role in meeting high global demands in the areas of mobility, energy, environ- ment, communication, health, nutrition and safety. Plas- tics enable tremendous savings in resources and energy as well as a wide variety of options in lightweight design. Particularly when they are fiber-reinforced, particle-filled, foamed or integrated into sandwich structures, plastics can withstand the highest degree of loading and absorb a great deal of energy. They can be supplemented with an additional range of functions such as protection from UV rays and the affects of weathering, reduced fire behavior, functions for the development of special optical properties, electric and thermal conductivity and with sensor and actuator functions.

At the same time, increasing demands on sustainability demand new solutions in terms of a circular economy and recycling or the development of bioplastics.

All components relevant for the implementation of sophisticated plastic applications, running the scope from basic natural science disciplines such as chemistry and physics, material sciences and material technology in processing to expertise in analytics, testing and modeling, are united at a high level under one roof.

The following three departments are complementary in their disciplines and methods.

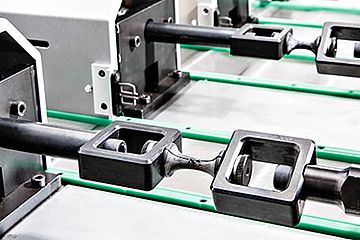

Polymer Processing and Component Design:

- Plastics processing: compounding, reactive extrusion and injection molding.

- Processing of the material into the component, prediction of mechanical properties.

- Interlinking of process- and material properties.

- Material modeling: material behavior under high strain rates and with multiaxial loading.

Polymer Synthesis:

- Development of chemical syntheses for monomers, polymers, additives, reactive modifiers.

- Technical synthesis optimization and upscaling.

- Development and screening of thermosets.

- Specific adjustment of interface and surface properties.

Formulation Development and Durability:

- Development of additives for customized modification of properties, e. g. with regard to material safety, reliability, failure characteristics, sustainability, resource efficiency.

- Materials analysis, polymer analysis and characterization.

- Development of analytical techniques.

- Kinetics of reactive processes.

Contact

Division director Plastics

- Dr. R. Pfaendner

- Phone: +49 6151 705-8605

- rudolf.pfaendner@lbf.fraunhofer.de