Trans4Mation25.

The world is currently undergoing a transformation – politically, socially and technologically. Digitalization, machine learning and Industrie 4.0 have the potential to change sustainably the global value creation. Besides, the awareness of climate change topics and sustainability has increased significantly in society as a whole.

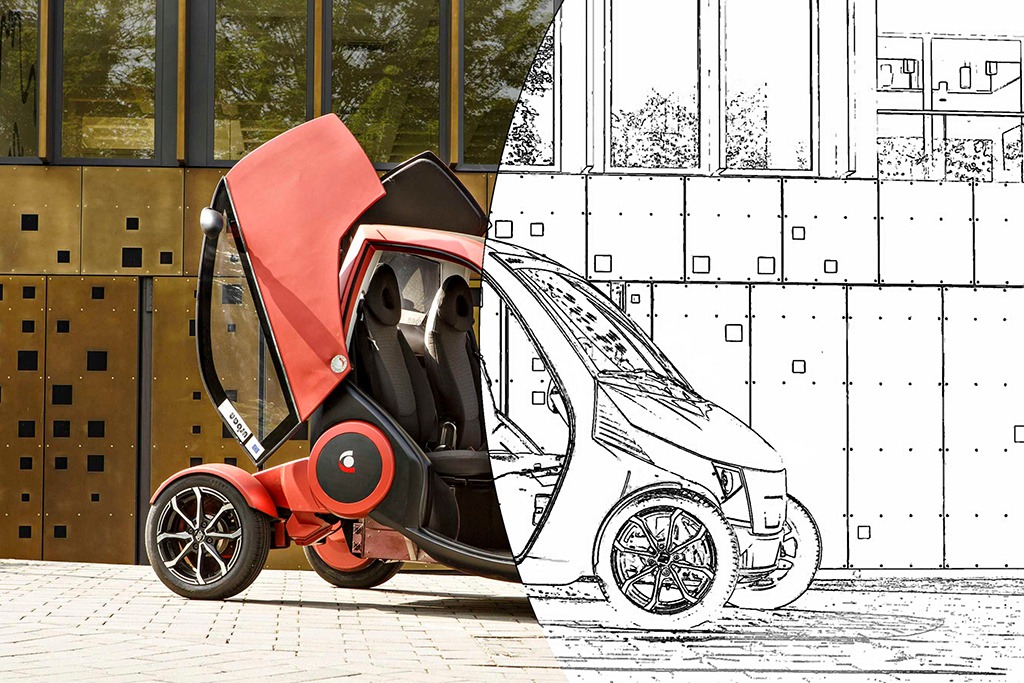

This can especially be seen in the area of transportation where energy and resource efficiency are gaining more and more importance compared to e.g. speed and comfort. Alternative drive and energy systems are playing an increasingly important role in research and development. In addition, autonomous vehicles and completely new mobility concepts will result in significant changes in our transport system.

Search, structure, evaluate

What does that mean to us as an industry-oriented research facility? What solutions will be necessary to meet these pressing social and industrial challenges? How can we make the best possible contributions by applying our expertise, scientific services, commitment and creativity? We have intensively discussed these questions for the past year, searching for and eventually obtaining answers to these questions by implementing a structured strategy process.

Since its foundation, Fraunhofer LBF has developed methods and procedures to design economically viable and safe lightweight structures. On the basis of this core of our research work, “the development of safe lightweighting solutions”, and underpinned by a range of indicators, we assume that safe, sustainable and cost-effective lightweighting will gain again importance in the transportation sector as well as in other sectors in the future. Recently, this has been reflected in the new lightweighting technology transfer program of the Federal Ministry for Economic Affairs and Energy, due to start in 2020.

However, in order to harness our potential, graded Dank materials, new production technologies (e.g. additive production), joined hybrid material systems or function integrated structures and new design and validation procedures are required. Due to their divers material mix and related manufacturing technology as well as their system-like complex behaviour, new multi-material systems needs to be developed through a consistent, digitized value chain accounting for the full life-cycle, from the system integration and production over the use phase to End-of-Life concepts. “The product generation process is thereby supplemented by the access, analysis as well as of feeding back of data both from product generation and increasingly from operations as well as downstream phases.”

New approaches, new solutions, new opportunities

Many of the elements mentioned are already the subject of our research today. However, they need to be harmonized and structured in a better, more efficient way. For this purpose, these activities have been pooled in a targeted manner as part of our strategy process and merged to focused, market-oriented R&D services. The implementation of these measures will be the focus of our work over the next five years.

Besides setting content-related focal areas and a marketoriented profiling of the existing research areas as well as their transformation into strategic business areas, three further strategic measures have been defined. As cross-divisional units, their purpose is to pool competences and services of the Fraunhofer LBF across all existing research areas, to identify new, high potential R&D areas and to transfer these to new services:

The Fraunhofer LBF continuously develops data-based approaches for the design of safe and reliable products. Within this context, the strategic measure Smart Digital Solutions aims for an efficient logging and cross-linking of data and processes over a full product life-cycle. By means of novel methods like machine learning, new insights will be derived enabling new development processes, enlarged R&D services as well as new products.

Cyberphysical Simulation & Testing's aim is to combine experimental and virtual design, verification and validation processes in a most efficient way enabling a reliable frontloading of technology assessment and selection in a product development process. Ultimately, this strategic measure should result in new methods for the optimal design of product feature in line with a reliability engineering.

Finally, the ultra-lightweight design strives for a significantly shift of limits of current designs. By means of condition and health monitoring concepts safety margin applied in view of material and operational limits should be reduced. Furthermore, the development of methods and tools are foreseen for tailoring of specific material and component properties, for the sensorisation of products as well as for functional graded or hybrid lightweight components.

Here we go

With the finalization of the strategy plan and successful evaluation in November 2019, two of these cross-divisional units were already implemented and staffed. Initial projects were acquired and started, research programs shaped and cooperative relationships strengthened and given new direction. As such, this review of the past year also marks the starting point for our path into the future, where the first steps are already visible. We hope that you, our customers and partners, will walk this path with us and we look forward to your company along the way.