Investigation of Limonene Residues in HDPE Bottle Material.

PLASTIC RECYCLING, PRESSURIZED WATER EXTRACTION, MATERIAL ANALYSIS

To date, the material quality of processed waste plastic has been inadequate for many applications, due mainly to the odor of recycled materials. An environmentally friendly extraction process was developed at Fraunhofer LBF in the laboratory scale in order to remove tracer artificial aromas from commercial HDPE plastic packaging. The procedure is carried out without the use of an organic solvent, which saves costs and protects the environment. An analysis carried out alongside the process delivers optimized procedural parameters through which a significant odor reduction of the samples is achieved after only one hour.

Improved material quality needed in processed plastic wastes

At present, the volume of plastic wastes generated per year is increasing significantly around the world. In order to recycle them in a manner that is environmentally sound and protects the climate, these plastic wastes need to be sorted and reprocessed to produce high-grade “post-consumer” recycled materials. Up to now, the recycling of plastic recyclable materials has been significantly restricted due to their reduced material quality, which is due mainly to their odor. Scientists at Fraunhofer LBF have developed a new process in the laboratory scale in order to remove artificial aromas from plastic packaging. The new procedure is based on pressurized water extraction and removes the Limes tracer aroma from commercial HDPE packaging.

New procedure removes aromas

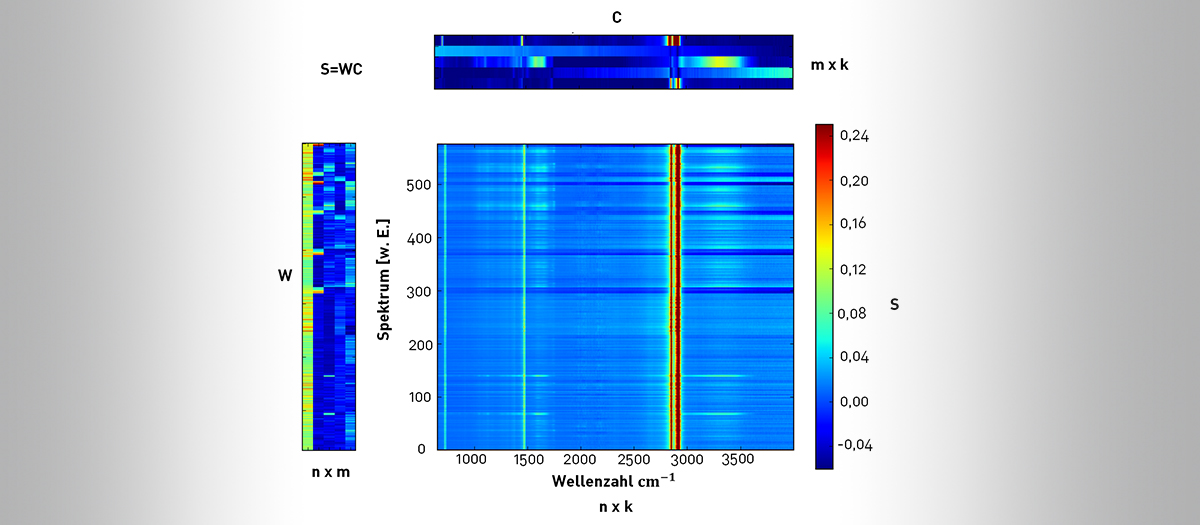

Analyses with infrared spectroscopy and mass spectrometry provide data on the chemical composition of the samples depending on various extraction conditions. The analytical data show that the samples contain far less Limes after extraction. Apart from the aroma, other additives and short-chain HDPE that were originally contained in the packaging are additionally removed from the samples. The optimum procedural parameters for the pressurized water extraction of aromas from HDPE packaging were determined based on several analyses. This is how odor reduction was achieved within a study, resulting in the improved material quality of processed plastic wastes.

Material analysis with machine learning methods optimizes extraction process

The project results show the benefits of a systemic approach to solving current plastic-related issues of significant social relevance. To develop the procedure, it was essential to gain detailed insights into the chemical kinetics of the extraction process. This was achieved by means of process-related analysis. By evaluating the data with the help of machine-learning methods, it was possible to optimize the extraction parameters within the scope of economic process management. At the current stage of development, an application scenario for the improved processing of waste plastics stands out for the new process.

Efficient process for all markets

Due to the underlying strategy, the process is equally suitable for industry, emerging and developing countries, meaning that it can potentially benefit all market participants who place plastic products on the market.

Sponsored as part of the internal programs of the Fraunhofer Society.

“Dealing with plastic waste in a better way helps protecting the environment. The extraction procedure developed indicates a route from disposed plastic waste to recycled plastics with a broadened spectrum of applications.” Dr. Guru Geertz, Fraunhofer LBF, Plastics Division

Contact

- Dr. Guru Geertz

- Phone: +49 6151 705-8733

- guru.geertz@lbf.fraunhofer.de

- M. Eng. Jan-Oliver Schoormann

- Phone: +49 6151 705-8803

- jan.oliver.schoormann@lbf.fraunhofer.de