Test bench Development: Multi-channel Test Bench to Determine Rubber Aging.

ELASTOMER AGING, ACTIVATION ENERGY, STRESS RELAXATION

(© Fraunhofer LBF)

Rubber materials in elastomer components such as absorbers, seals, conveyor belts or tires change their properties under the influence of thermal or mechanical loads. Product development and life span prediction therefore require that the underlying aging and failure mechanisms be understood and modelled. A key parameter for life span prediction is the activation energy of the thermal degradation of the elastomer network. The comparison of stress relaxation experiments and cyclical structural durability tests (Wöhler curves) during the thermal aging of elastomers showed no difference between the activation energies in both tests. This enables the activation energy to be determined relatively easily and cost-effectively based on time-resolved measurements of the stress relaxation at various temperatures. A newly constructed multi-channel test bench for the stress relaxation of elastomers enables the simultaneous testing at six temperatures.

Stress relaxation measurements on elastomers

Stress relaxation is one of few methods, which can be used to track the aging of elastomer samples continuously. In the process, a tensile test specimen is brought to the aging temperature, and after a one-time application of a specific amount of strain (e.g. 10%), the tensile force on the specimen is measured continuously. Aging processes in the sample cause physical and chemical cross-linking points to be broken down and polymer chains “severed”. As a result, previously strained polymer chains can relax, which leads to a reduction in tensile stress during the aging. Depending on the temperature, these measurements take several weeks to months.

Time saving in material development through parallel testing

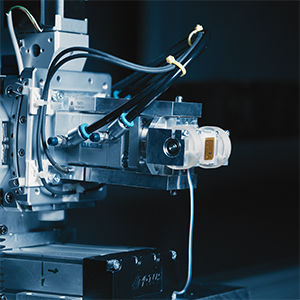

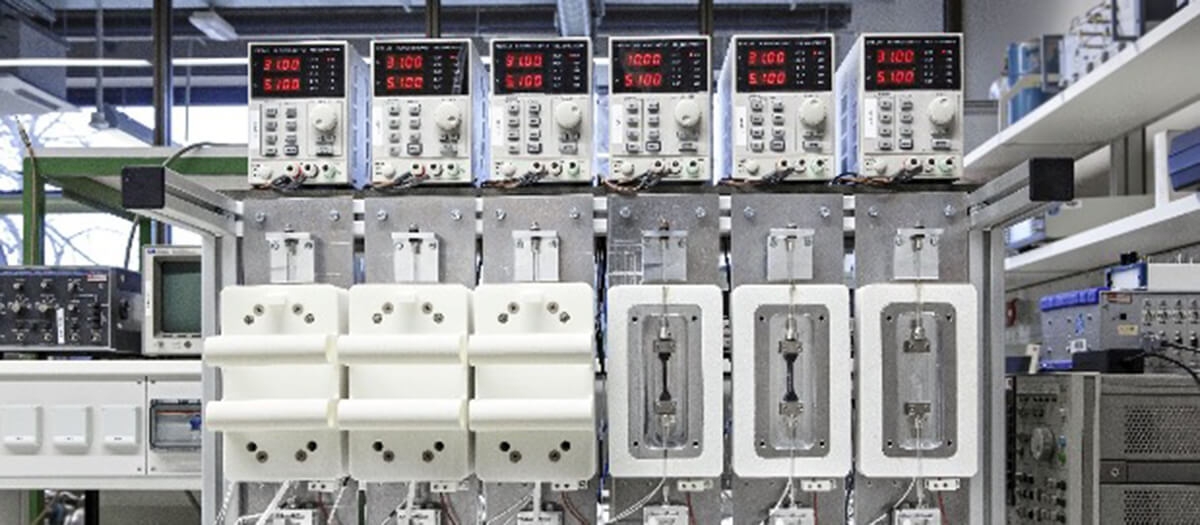

The process is significantly accelerated by conducting multiple stress relaxation measurements in parallel at several temperatures. For this purpose, a parallelized measuring station was developed and assembled with six separately temperature controlled test chambers (Figure 1) in the Division Plastics of Fraunhofer LBF. In each of these chambers, a sample can be subjected to a constant temperature and displacement. A force sensor is used to acquire the remaining tensile force over the entire test period.

In order to determine the activation energy, an evaluation algorithm based on a “master curve construction” was developed. The activation energy can be determined from the logarithmic shift factors by plotting them in an Arrhenius diagram and fitting them with the Arrhenius equation. It turned out that the activation energies obtained in this way correspond very well with the activation energies from very complex cyclic fatigue experiments on samples aged for different times and at different temperatures.

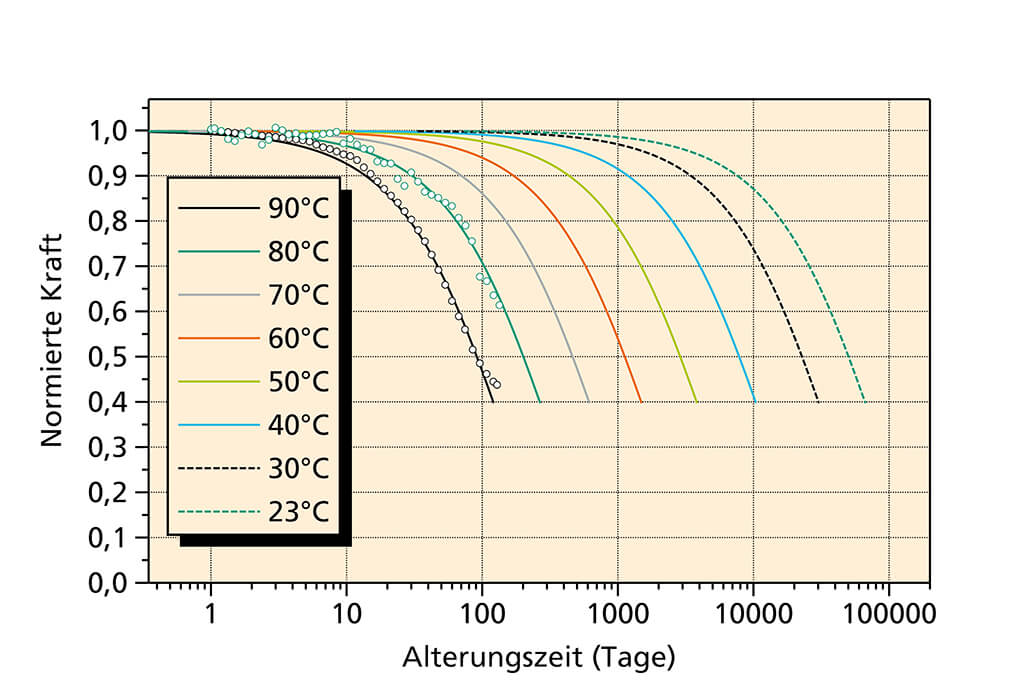

Based on this, the shift factor for a given temperature can be calculated, and the tensile force-time curve can be predicted for any temperature (Figure 2). This allows the estimation of the life time for aging and failure processes. The activation energies obtained by the stress relaxation experiments and by cyclical fatigue strength tests (Wöhler curves) agree. This enables the measurement effort to be reduced and leads to significant time savings in material development.

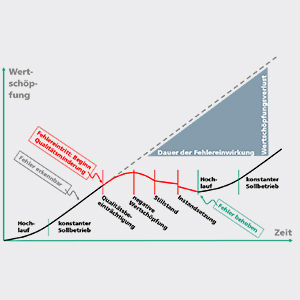

Improved life time predictions for the application case

Elastomers are used across a wide range of day-to-day applications. They can be found, for example, in tires, conveyor belts, seals, coatings, in the shoe and textile industry and in many other areas. For developers and users of elastomers, knowledge of the expected aging process depending on the operating temperature is very important. The multi-channel test bench enables measurements of the aging process to be carried out simultaneously at different temperatures, thus saving time. The course of aging at any temperature can then be extrapolated from the measurement data. This leads to significant time savings in material selection and development as well as to an improved quality of the life time prediction.

Summary

A measurement station for simultaneous measurements of the stress relaxation on elastomers at various temperatures is presented. The multi-channel measuring station consists of six test chambers whose temperatures can be set independently. The tensile force-time curves measured at the individual temperatures can be combined to form a master curve. From the shift factors, the typical activation energy of the aging processes is obtained. Extrapolation of the data also makes it possible to predict the course of aging for any other temperature.

Contact

- Dr. Dirk Lellinger

- Phone: +49 6151 705-8667

- dirk.lellinger@lbf.fraunhofer.de

- Priv.-Doz. Dr. Ingo Alig

- Phone: +49 6151 705-8659

- ingo.alig@lbf.fraunhofer.de