Cost-effective and sustainable lightweight construction through efficient numerical methods.

NUMERICAL SIMULATION, EFFICIENT PRODUCT DEVELOPMENT

(© Fraunhofer LBF)

Until now, the high price of lightweight components has presented an obstacle to their thorough and comprehensive application in the automotive sector. If lightweight construction is to prevail for the majority of mounted automotive components, its overall operating costs have to be reduced. For this purpose, six large automotive manufacturers, six component and materials suppliers as well as various research institutes have joined forces in the “ALLIANCE” EU project.

Parametric models for multi-faceted application

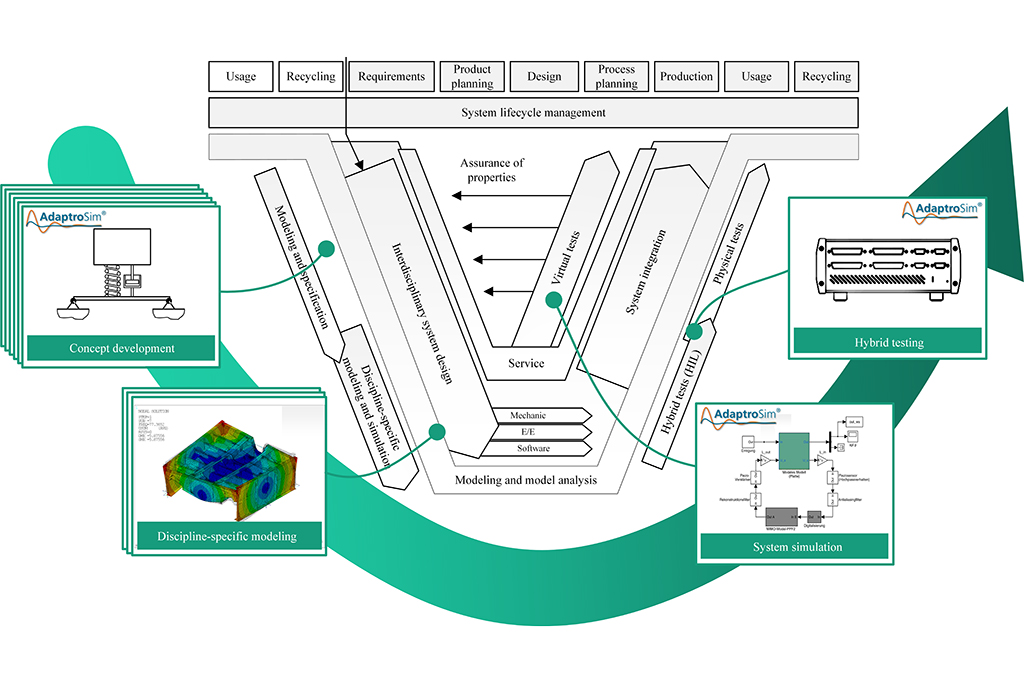

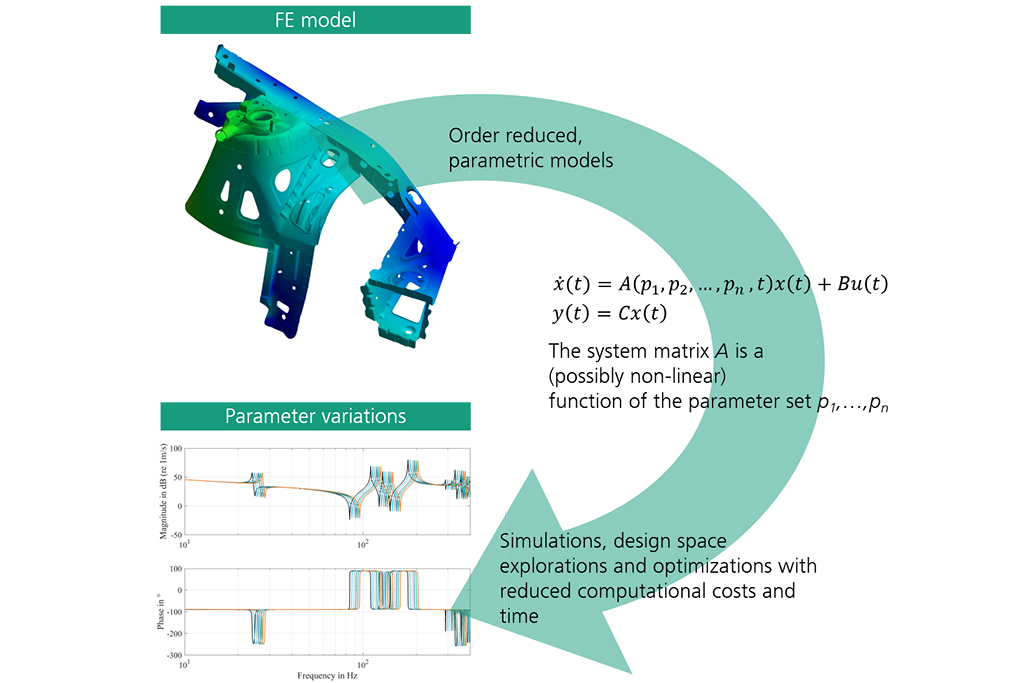

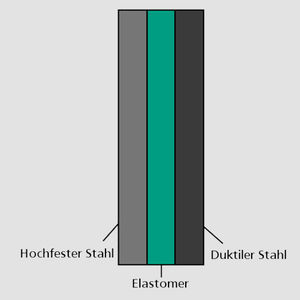

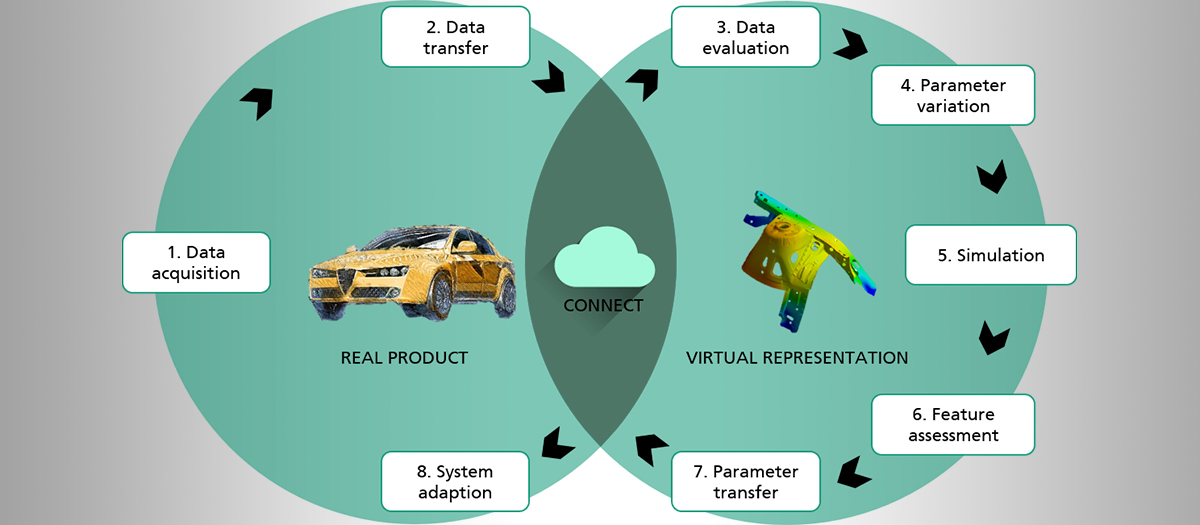

In the project, scientists at Fraunhofer LBF developed parametric and efficient numeric models for individual vehicle components. These components were described in detail using Finite-Element models and simplified by parametric model order reduction methods to the point where they can be solved in time-domain or in real-time simulations. Multidisciplinary multi-objective optimization enables optimal design parameters to be determined and allows for the observation of interactions between highly diverse physical (e.g. mechanical, acoustic) and non-physical (e.g. costs, environmental impact) domains. In addition, the virtual prototype may be integrated on system level efficiently and in a targeted manner, thus helping to simplify and accelerate the development

process. The mechanical properties, costs and resulting global warming potential have been observed and evaluated comprehensively for the life cycle of lightweight components in the “ALLIANCE” project.

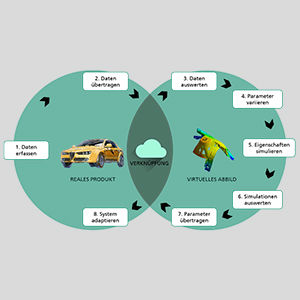

The optimization of the material properties of components can also be carried out in combination with vibration reduction measures (e.g. absorbers, insulation, active engine mounts) in relation to lightweight construction, NVH and costs. Frequency or amplitude-dependent material properties can also be defined through the parametric description of the order-reduced model. In the context of digitization, possible application scenarios additionally arise as digital twins for the developed parametric models. The real-time numerical models generated during the development phases may be used during operation for condition monitoring and control in the future. The values calculated in the model are used during the observation as virtual sensor systems or to carry out an automated online model comparison.

Lightweight construction does not need to be expensive

Overall, in the “ALLIANCE” project, lightweight designs and technologies were developed and consistently evaluated and optimized on system level in terms of savings of mass, costs and global warming potential. In various vehicle components, the weight could be reduced by up to 30 percent – and this at costs of only 3 euros per kilogram saved.

The ALLIANCE project received funding from the European Union’s Horizon 2020 research and innovation programme under grand agreement No 723893.

Contact

- Dipl.-Ing. Christoph Tamm

- Phone: +49 6151 705-8431

- christoph.tamm@lbf.fraunhofer.de