High-voltage Energy Storage in Lightweight Design for Electrified Semi-trailers.

ENERGY STORAGE UNITS, ULTRA-LIGHTWEIGHTING, SEMI-TRAILERS, ELECTROMOBILITY.

(© Fraunhofer LBF)

At 18%, the transportation sector is the third-largest producer of CO2 emissions in Germany. In the area of freight transport, trucks make up around 72 percent of the entire transport output. In February 2019, the European Parliament and the European Commission therefore set binding goals for the CO2 reduction of heavy utility vehicles. Alongside an improved carbon footprint, the discussions on inner-city driving bans for diesel vehicles promote the development and use of trucks with alternative drives. Current studies assume that a quarter of all new trucks will be sold with alternative drives in Germany in 2030. For long-haul freight transport and the mileages that are standard in that area, battery electrical vehicles are a difficult design to implement due to the sizable mass and cost of the electrochemical energy storage units.

Hybrid-electrical tractor units or new drive designs for utility vehicle trailers offer other emissions-reducing possibilities. In a joint research project sponsored by the Federal Ministry for Economic Affairs and Energy, Fraunhofer LBF developed a particularly light high-voltage energy storage unit for an electrically-driven semi-trailer.

Flexible thanks to thin film sensor systems

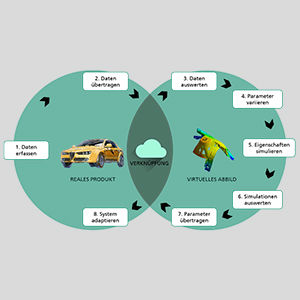

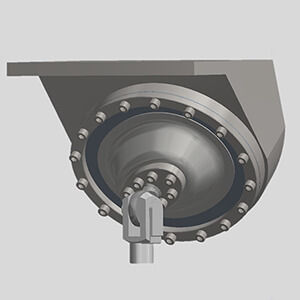

A self-sufficient semi-trailer vehicle with an electrical drive module was developed as part of the joint research project sponsored by the Federal Ministry for Economic Affairs and Energy during the period from 2016 to 2019. The traction components of the module are dimensioned in a way that enables brake energy recovery plus short-term traction assist as well as load point shifting of the tractor units. This leads to significantly improved fuel efficiency, which can also be achieved in long-haul transport. The evTrailer was equipped with an innovative thin film sensor system integrated into the kingpins as well as built-in control and regulating technology. This means that only a minimum of vehicle communication is required and allows for a drive mode which is independent of the tractor unit and operates at low speeds, e.g. in the logistics center.

Based on the experience gained in electromobility, a variety of single cells were used in the 18650 form factor and with lithium metal oxide cathode material for the battery. The energy storage system itself had an overall capacity of 100 kWh and a voltage range of between 590 and 670 V. This meant that over 10,000 single cells had to be arranged within a 168s60p system configuration. Mileage of at least 700,000 km had to be proven for long-term use: In extensive investigations on the degradation of the selected cells, it was determined that the discharge hub had to be limited to 50% of the maximum possible capacity.

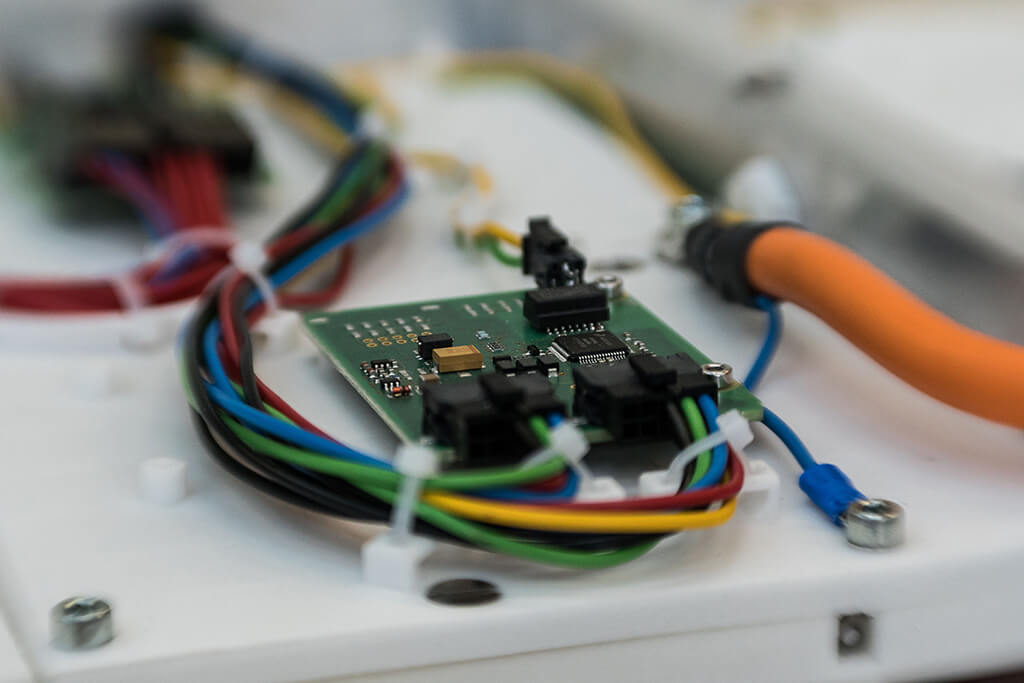

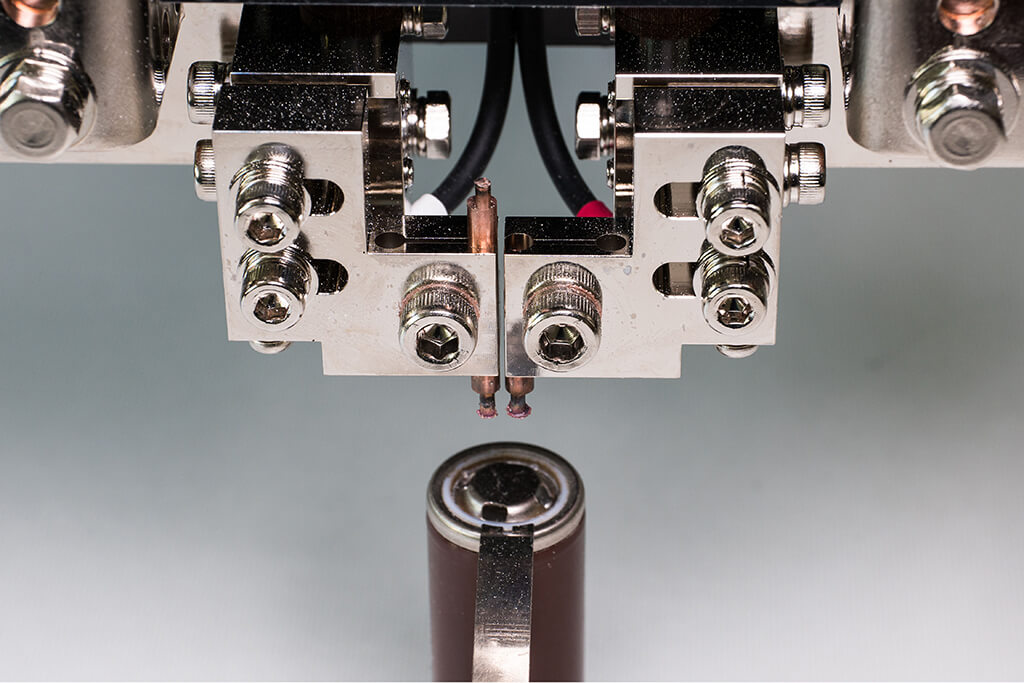

Development of special battery connectors

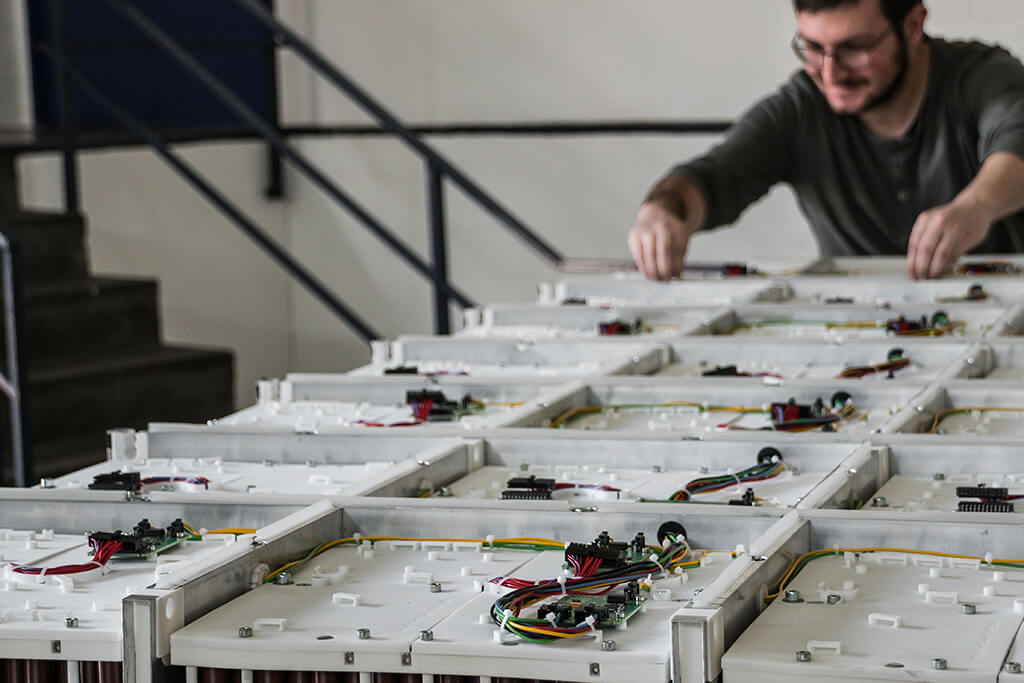

Due to the many tolerances in the contact positions which are possible among the wide range of single cells, there is a need to develop special power connectors and to produce these using electrolytically nickel-plated cold strip, then connect them to the cells by means of spot welding. Each of the individual modules were fitted with 240 cells and designed additively with the aim of achieving maximum functional integration, so all of the necessary geometric features were taken into account in cell integration, high-voltage and low-voltage cabling as well as the integration of the BMS components. In the housing, two modules were each piled up one above the other in a mirrored layout and a cooling plate was placed between them.

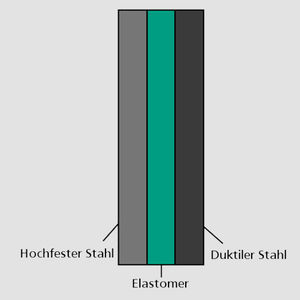

Light battery housing compensates for cell weight

Despite a mass of 475 kg for the total number of cells alone, it was possible to limit the total mass of the energy storage unit including cooling system, BMS and housing to just over 600 kg: The lightweight housing design which this required used progressive sandwich structures and glass fiber-reinforced thermoplastics. This enabled a cell mass to overall weight ratio of 0.8 to be achieved. This ratio is particularly favorable for high-voltage energy storage units.

Such an ultra-lightweighting solution for a high-voltage energy storage unit makes designs such as the evTrailer possible and helps develop potential ways of achieving the CO2 reduction goals in freight transport.

Fewer emissions, improved driving dynamics and self-sufficient maneuvering

The electrical drive of the trailer allowed for consumption savings and a reduction in CO2 emissions of approx. 20% to be achieved for the vehicle as a whole. The extra axle drive meant that traction properties was also able to be improved. The electrical drive also enables self-sufficient maneuvering of the trailer.

This project was sponsored by the Federal Ministry for Economic Affairs and Energy (BMWi) under the sponsorship code 01MY15006.

Contact

- Rüdiger Heim

- Phone: +49 6151 705-283

- ruediger.heim@lbf.fraunhofer.de